30-40 iitoni/ngosuku Gqibezela iParboiled Rice Milling Plant

Ingcaciso yeMveliso

I-paddy parboiling njengegama legama yinkqubo yokushisa kwamanzi apho i-starch granules kwinkozo yerayisi igalelwa igelatin ngokugalelwa komphunga kunye namanzi ashushu.I-Parboiled irayisi yokugayaisebenzisa irayisi eqhunyiweyo njengento ekrwada, emva kokoumahluli wepaddyukucoca, ukucwina, ukupheka, ukomisa kunye nokupholisa emva kokunyanga ubushushu, uze ucinezele indlela eqhelekileyo yokulungisa irayisi ukuvelisa imveliso yerayisi. Irayisi egayiweyo egqityiweyo ifunxe ngokupheleleyo isondlo serayisi kwaye inencasa entle, kwaye ngexesha lokubiliswa yabulala izinambuzane kwaye yenza irayisi ukuba igcinwe lula.

Siyakwazi ukubonelela ngeemoto zangokugqibezela isityalo sokusila irayisingothotho lwesakhono semveliso kwimfuno yakho. Isityalo sokungqusha irayisi esipheleleyo senziwe ngamalungu amabini aphambili: icandelo lokubilisa irayisi kunye necandelo lokusila irayisi.

Iimbonakalo

1) Ukucocwa kwePaddy:Kweli nqanaba sisusa ukungcola kwi-paddy.

Irayisi kufuneka icocwe kuqala ukususa iindiza, amatye, intambo ye-hemp, enye inkunkuma enkulu kunye nokungcola okufana nothuli oluxutywe kwirayisi. Ukuba i-paddy inothuli xa imanzisa iya kungcolisa amanzi kwaye ibe nefuthe kwisondlo serayisi. Kwakhona, emva kwenkqubo yokucoca, ukungaphumeleli kwezixhobo zokucwangcisa ezantsi okanye umonakalo kumacandelo kunokuphetshwa ngokufanelekileyo, okuyinkqubo ephambili yesethi epheleleyo yezixhobo ze-rice parboiling.

2) Ukufunxwa kwePaddy:Injongo yokufunxwa kukwenza ipaddy ifunxe amanzi aneleyo, idale iimeko zokuncamathisela istatshi. Ngexesha lesitatshi sokuncamathisela ipaddy kufuneka ifunxe amanzi angaphezu kwama-30%, okanye ayizukwazi ukutshisa ngokupheleleyo ipaddy kwinyathelo elilandelayo kwaye ngaloo ndlela ibe nefuthe kumgangatho werayisi.

a. Ngokucofa, ubushushu obungaguqukiyo, kunye nokufunxwa koxinzelelo, amanzi afunxwa ngokupheleleyo yirayisi ngexeshana elifutshane, ukuze umthamo wamanzi erayisi ufikelele ngaphezu kwama-30%, okuyimeko eyimfuneko yokuba isitatshi serayisi sigalelwe ngokupheleleyo. ngexesha lokupheka. Kumgca wokuvelisa irayisi, eli candelo liyisiseko kunye necandelo elibalulekileyo.

b. Ngokuxhomekeke kwiindidi kunye nomgangatho werayisi, ukushisa okumanzi ngokuqhelekileyo kungama-55-70 degrees, kwaye ixesha lokucwina yi-3.5-4.5 iiyure.

3) Ukutshisa kunye nokubilisa:Emva kokuntywila ngaphakathi kwi-endosperm inamanzi aneleyo, ngoku lixesha lokutshisa i-paddy ukuqonda ukuncamathisela kwesitatshi. Ukuphunga kunokutshintsha isakhiwo somzimba werayisi kwaye ugcine isondlo, ukwandisa umlinganiselo wemveliso kwaye wenze irayisi igcinwe lula.

Kule nkqubo, i-high-pressure kunye ne-high-temperature steam isetyenziswa. Ubushushu, ixesha, kunye nokufana kwe-steaming kufuneka kulawulwe ngokungqongqo ukwenzela ukuba isitashi erayisi sibe negelatin ngokupheleleyo ngaphandle kokugqithiswa.

Xa isitatshi gelatinization ngokwaneleyo, umbala kusetyenzwa egqityiweyo irayisi parboiled is transparent honey-colored.

Ngokuhlengahlengisa iiparamitha zokupheka, irayisi egayiweyo enombala okhanyayo, umbala ongaphantsi kobumnyama, kunye nombala omnyama unokucutshungulwa ngokweemfuno zabathengi.

4) Ukomisa iPaddy eParboiled:Injongo yokomisa kukwenza ukufuma kuncitshiswe ukusuka malunga ne-35% ukuya malunga ne-14%, ukunciphisa ukufuma kunokwenza irayisi igcinwe lula kwaye ihanjiswe, kwaye yandise kakhulu umlinganiselo wemveliso, njengoko ubuninzi bezinga lerayisi linokufumaneka xa irayisi milled.

Sisebenzisa ukushisa kwebhoyila ngeli xesha le nkqubo, iguqulwa ibe yimoya ngokusebenzisa umshicileli wokushisa, kwaye irayisi yomiswe ngokungathanga ngqo, kwaye irayisi eyomileyo ayinakho ukungcola kwaye akukho phunga elikhethekileyo.

Inkqubo yokomisa ihlukaniswe ngamanqanaba amabini. Inqanaba lokuqala kukomisa ngokukhawuleza, okunciphisa ukufuma kwepaddy ukusuka ngaphezulu kwe-30% ukuya malunga ne-20%, kwaye emva koko ukomisa ngokukhawuleza ukwenza i-paddy icothe ngokupheleleyo kwaye inciphise izinga lokugqabhuka esinqeni. Phucula umlinganiselo wemitha yonke.

5) Ukupholisa iPaddy eParboiled:I-paddy eyomileyo ithunyelwa kwisitoreji esithe nkqo ukuze igcinwe okwethutyana ukuze icothiswe ngokupheleleyo kwaye ipholile ngaphambi kokuba iqhutywe. Indawo yokugcina isilinda ethe nkqo ixhotyiswe ngefeni yokungenisa umoya, enokukhupha ubushushu obuseleyo. Kwaye wenze ukufuma kwerayisi ngokulinganayo.

6) Irayisi Husking kunye nokwahlula:Ukusebenzisa umatshini wokuthunga irayisi ukususa ikhoba lephedi eyomileyo. Emva kokucwina kunye nokutshisa kuya kuba lula kakhulu ukuxubha i-paddy kunye nokugcina amandla.

Isahluli se-paddy sisetyenziswa kakhulu ukwahlula irayisi emdaka kwi-paddy ngokwahluka kwabo kubunzima obuthile kunye ne-friction coefficient kumacandelo amathathu: i-paddy, irayisi emdaka, kunye nomxube wazo zombini.

7) Ukugaya irayisi:Iperile yerayisi ephekiweyo ixabisa ixesha elininzi kunepaddy eqhelekileyo. Isizathu kukuba emva kokufunxa irayisi kulula ukuba ube smectic. Ukuze siphephe le ngxaki, sisebenzisa ukuvuthela irayisi miller kwaye sonyuse isantya esijikelezayo se-rice miller, ukuhanjiswa kwebran yerayisi kuthathe uhlobo lwe-pneumatic ukunciphisa ukukhuhlana.

Umatshini wokusila irayisi uphuhliselwe ukugaya irayisi, obubuchwephesha obuphambili behlabathi lokusila irayisi mhlophe ngoku ukwenza ubushushu berayisi buhle, isiqulatho sebran sibe sezantsi, kunye nokwanda okwaphukileyo kusezantsi.

8) Ukupholisha irayisi:Inkqubo yokupolisha irayisi kukupolisha umphezulu werayisi ngokutshiza amanzi, nto leyo eyenza ukubunjwa kwe-gelatinous layer egudileyo eyandisa ixesha lokugcinwa. Igumbi lokupholisha elongeziweyo ukuvelisa irayisi ekumgangatho ophezulu. Irayisi elungileyo iza ngomatshini wokupolisha, iya kwenza irayisi yokusila ibe nombala omhle ngakumbi kwaye ikhazimle, ngaloo ndlela inyuse umgangatho werayisi.

9) Ukuhlelwa kwerayisi:Umatshini wokulinganisa irayisi usetyenziselwa ukuhluza irayisi egayiweyo ngokufanelekileyo nangokuchanekileyo kwiiklasi ezininzi: irayisi yentloko, enkulu eyaphukileyo, eyaphukileyo ephakathi, eyaphukileyo encinci, njl.

10) Ukuhlela Umbala Werayisi:Irayisi esiyifumana kwinqanaba eliphezulu isenayo irayisi embi, irayisi eyaphukileyo okanye ezinye iinkozo okanye ilitye. Ke apha sisebenzisa umatshini wokukhetha umbala ukukhetha irayisi embi kunye nezinye iinkozo.

Umatshini wokuhlela umbala ngumatshini obalulekileyo wokuqinisekisa ukuba sinokufumana irayisi ephezulu. Ukusebenzisa umatshini wokuhlela umbala werayisi ukulungisa okubi, ubisi, i-chalky, i-paddy, kunye nemathiriyeli yangaphandle. Umqondiso weCCD ngelixa ungacwangciswanga uvavanyiwe. Ukuba kufunyaniswe ukuba kukho irayisi engafanelekanga okanye ukungcola kwizinto eziphathekayo, i-ejector iya kuvuthela iimpahla eziphosakeleyo kwi-hopper.

11) Ukupakishwa kwerayisi okugqityiweyo:Irayisi yokugqiba ngoku ilungile sithandwa nonke! Masisebenzise umlinganiso wethu ozenzekelayo kunye nomatshini wokupakisha ukuzenza zibe yi-5kg 10kg okanye i-50kg yeengxowa.

Lo matshini wokupakisha ukulinganisa okuzenzekelayo uquka ibhokisi yezinto eziphathekayo, isikali sokupakisha, umatshini wokuthunga, kunye nebhanti lokuhambisa. Iyakwazi ukusebenzisana nomsebenzi kunye nayo yonke imizila yemveliso yerayisi yemodeli. Luhlobo lombane, ungayiseta njengekhompyuter encinci, emva koko iya kuqalisa ukusebenza. Kuba ukupakisha umthamo bag ungakhetha 1-50kg ingxowa nganye ngokwesicelo sakho. Kulo matshini uya kufumana uhlobo lwengxowa yerayisi kwaye ungabonelela ngerayisi yakho kubo bonke abathengi bakho!

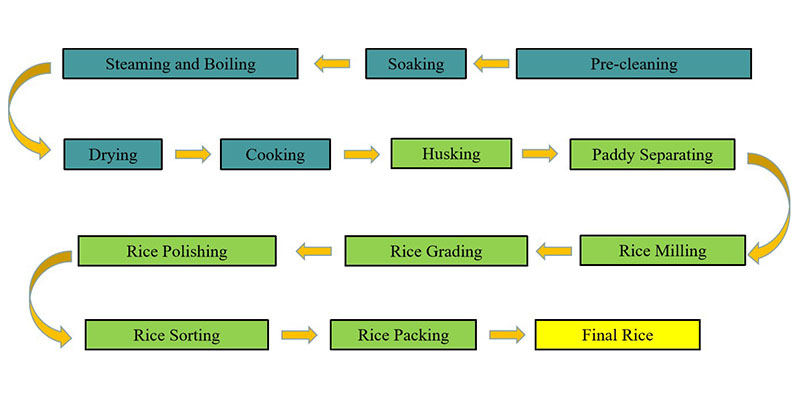

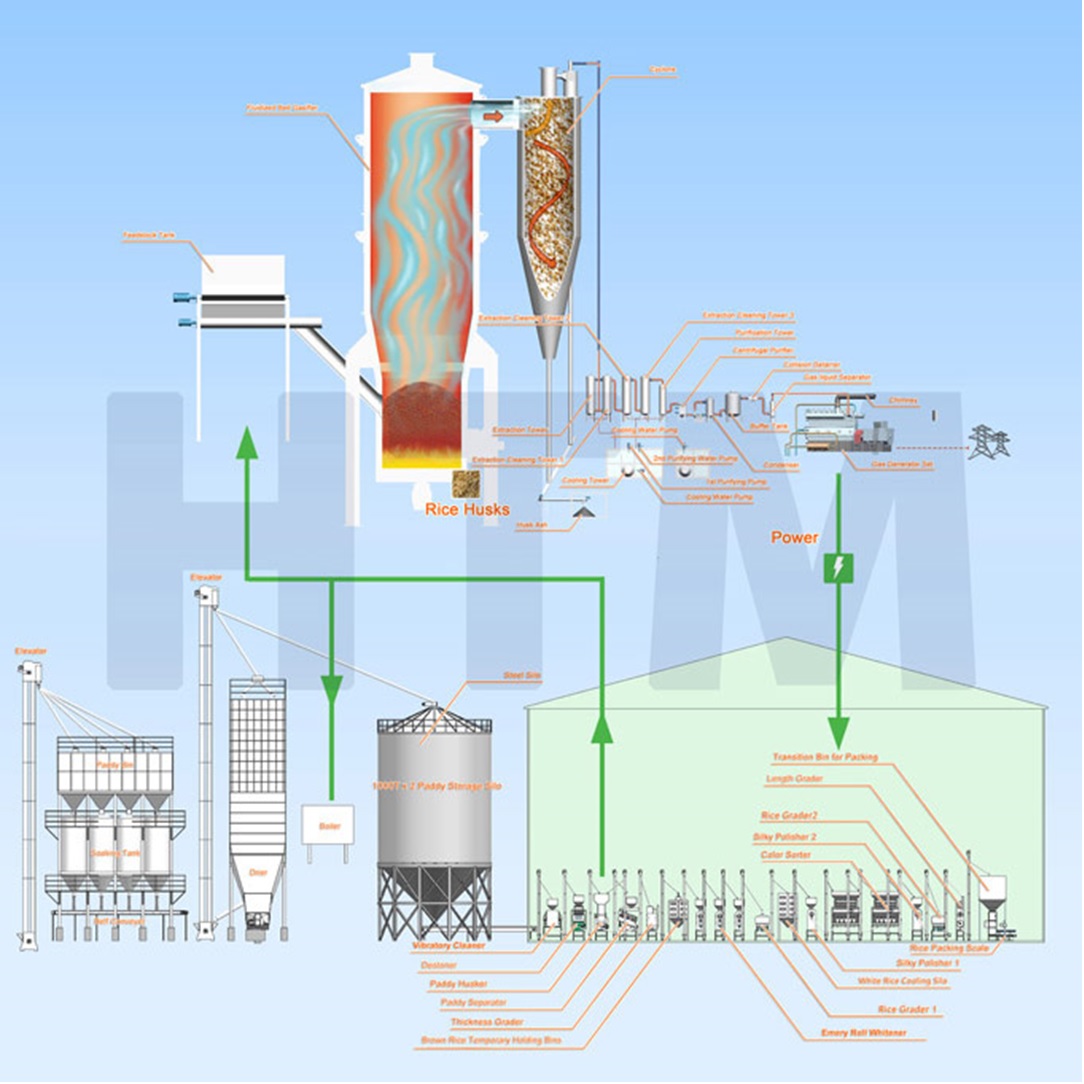

Inokubonwa kwinkqubo yokusetyenzwa kwerayisi ephothiweyo ukuba inkqubo yokuvelisa iseti epheleleyo yesityalo se-paddy sisekwe kwitekhnoloji yokulungiswa kwerayisi emhlophe, ukongeza iinkqubo zonyango lwe-hydrothermal ezifana nokuntywila, ukubila nokubilisa, ukomisa nokupholisa, kunye nokucotha ukupheka. Iyonke inkqubo yemveliso yerayisi egayiweyo ibandakanya iinxalenye ezimbini: inxalenye yerayisi yokubilisa kunye nenxalenye yokugaya irayisi, efana nale:

Icandelo le-A.Rice Parboiling:

Ipadi ekrwada → Ukucoca kwangaphambili → Ukufunxwa → Ukuphunga nokubilisa → Ukomisa → Ukupholisa → Ukugalela irayisi

ICandelo le-B.Rice Milling:

IPaddy eBotshiweyo → UkuHusking kunye nokwahlula → Ukugaya irayisi →Ukupolisha irayisi kunye noHlelo → Ukuhlela uMbala weRayisi

Umgaqo wokukhetha imveliso yesityalo sokuxutywa kwepaddy ixhomekeke ikakhulu kwimveliso kunye namandla omatshini wokungqusha irayisi olandelayo. Kufuneka kubekho isixa esaneleyo serayisi ephekiweyo phambi kokuba inkqubo yokuthunga irayisi iqhube. Imveliso yezixhobo ezifakwe ngaphambili kufuneka ibe mkhulu kunemveliso yerayisi elandelayo. Ukuba oko akwanelanga, iiyunithi ezimbini zinokudityaniswa ngokuhambelanayo. Xa imveliso ihambelana, sebenzisa i-rice pre-parboiler enamandla amancinci.

Uvulindlela kushishino, sisebenza ekwenzeni uluhlu olugqibeleleyo lwePaddy Parboiling Plant. Sinokubonelela ngesityalo esipheleleyo kwaye sinikezela ngenkonzo yokufakela kunye nenkonzo yoqeqesho. Ukuba unomdla kule projekthi, nceda uzive ukhululekile ukuqhagamshelana nathi ngolwazi oluthe vetshe.

Iimbonakalo

1.Izityalo zethu zeParboiling & Drying zenziwe ngezinto eziphambili kwaye zivavanyiwe zomgangatho wokuqala. Eyomeleleyo eyenziwe yakhiwe ngokulula iqinisekisa ukusebenza okungenangxaki kunye nomgangatho ongcono ofanayo.

2.Umphunga olinganayo wepaddy wenziwa ukuba kwenzeke ngenkqubo yokusasaza umphunga kumatanki, Umgangatho opheleleyo we-paddy efanayo malunga nokupheka kunye nokomisa.

3.Amatanki amabini amanzi anikezelwa phezulu njengoko amanzi abandayo kulula ukuwaphakamisa.

4.Akukho kuchithakala njengoko ukuphakama okwandisiweyo kwesityalo kuqinisekisa ukuhamba kakuhle kwetaper kwipaddy emanzi.

5.Ukomiswa ngendlela efanayo kwerayisi, iibhafu ezishinyeneyo zokomisa kancinane nangokuzinzileyo ngaphandle kokwenziwa kweenkozo ezaphukileyo.

I-6.I-Factory ifakwe kunye nesityalo esidibeneyo kwi-bolting ngokupheleleyo kunye nezakhiwo zokugoqa, i-90% yezinto eziphathekayo zenziwe kwifektri yethu, ixesha elincitshisiweyo elithathwe ngexesha lofakelo.

I-7.Ukusetyenziswa kwamandla aphantsi ngenxa yoyilo olusebenzayo lwee-blowers kunye ne-elevators.

8.Abasebenzi abaphantsi abafunekayo ekusebenzeni kweyunithi njengoko uninzi lwemisebenzi izenzekelayo.