Inkqubo yokucoca i-oyile etyiwayo: i-water Degumming

Ingcaciso yeMveliso

Inkqubo yokucoca i-oyile kwisityalo sokusulungekisa i-oyile kukususa ukungcola kweentsini kwi-oyile ekrwada ngeendlela zomzimba okanye zekhemikhali, kwaye linqanaba lokuqala lokusulungekiswa kwe-oyile / inkqubo yokucoca. Emva kokucofa ngokucofa kunye nokutsalwa kwe-solvent kwi-oilseeds, i-oyile ekrwada iqulathe ikakhulu i-triglycerides kunye nee-non-triglyceride ezimbalwa. Ukubunjwa kwe-non-triglyceride kuquka i-phospholipids, iiprotheni, i-phlegmatic kunye noshukela kuya kusabela kunye ne-triglycerides ukwenza i-colloid, eyaziwa ngokuba yi-gum ukungcola.

Ukungcola kwegum akuchaphazeli nje kuphela ukuzinza kweoli kodwa kuchaphazela umphumo wenkqubo yokucoca ioli kunye nokucubungula okunzulu. Ngokomzekelo, ioli e-non-degummed kulula ukwenza ioli e-emulsified kwinkqubo yokucoca i-alkaline, ngaloo ndlela yandisa ubunzima bokusebenza, ilahleko yokucocwa kweoli, kunye nokusetyenziswa kwezinto ezincedisayo; kwinkqubo ye-decolorization, i-oyile e-non-degummed iya kwandisa ukusetyenziswa kwe-adsorbent kunye nokunciphisa ukusebenza kwe-discoloring. Ke ngoko, ukususwa kwetshungama kuyimfuneko njengenyathelo lokuqala kwinkqubo yokucoca ioyile ngaphambi kokuba i-oyile idecicide, i-oyile decolorization, kunye ne-oyile deodorization.

Iindlela ezithile ze-degumming ziquka i-hydrated degumming (i-water degumming), i-asidi yokucoca i-degumming, indlela yokucoca i-alkali, indlela ye-adsorption, i-electropolymerization kunye ne-thermal polymerization method. Kwinkqubo yokucoca ioli edliwayo, eyona ndlela isetyenziswa ngokuqhelekileyo i-hydrated degumming, enokuthi ikhuphe i-phospholipids ye-hydratable kunye nezinye i-phospholipids ezingenayo i-hydrate, ngelixa i-phospholipids eseleyo engekho-hydrate kufuneka isuswe nge-acid refining degumming.

1. Umgaqo osebenzayo we-hydrated degumming (i-water degumming)

I-oyile ekrwada evela kwinkqubo yokukhutshwa kwe-solvent iqulethe amacandelo e-soluble yamanzi, ngokuyinhloko aqulethwe yi-phospholipids, efuna ukususwa kwioli ukwenzela ukuba imvula encinci ivule kwaye ihlale ngexesha lokuthuthwa kweoli kunye nokugcinwa kwexesha elide. Ukungcola kweentsini ezifana ne-phospholipids kunempawu ye-hydrophilic. Okokuqala, ungashukumisa kwaye wongeze isixa esithile samanzi ashushu okanye isisombululo se-electrolyte emanzi njengetyuwa kunye ne-phosphoric acid kwi-oyile ekrwada eshushu. Emva kwexesha elithile lokusabela, ukungcola kweentsini kuya kuthungwa, kuthotywe kwaye kususwe kwioli. Kwinkqubo ye-hydrated degumming, ukungcola ikakhulu yi-phospholipid, kunye neeprotheni ezimbalwa, i-glyceryl diglyceride, kunye ne-mucilage. Ngaphezu koko, iintsini ezikhutshiweyo zinokulungiswa zibe yi-lecithin yokutya, isondlo sezilwanyana okanye ukusetyenziswa kobugcisa.

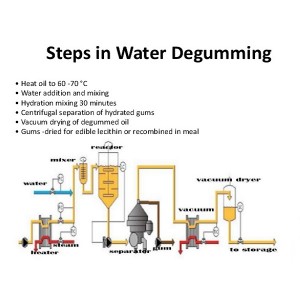

2. Inkqubo ye-hydrated degumming (i-water degumming)

Inkqubo yokucoca amanzi ibandakanya ukongeza amanzi kwi-oyile ekrwada, ukufaka amanzi kwizixhobo ezinyibilikayo emanzini, emva koko kususwe uninzi lwazo ngokwahlukana kwe-centrifugal. Isigaba sokukhanya emva kokuhlukana kwe-centrifugal yi-oyile ye-degummed ekrwada, kwaye isigaba esinzima emva kokuhlukana kwe-centrifugal yindibaniselwano yamanzi, izakhi ezinyibilikayo emanzini kunye neoli edibeneyo, ngokudibeneyo ebizwa ngokuba "iintsini". I-oyile ekrwada ye-degummed yomiswa kwaye ipholiswe phambi kokuba ithunyelwe kwindawo yokugcina. Iintsini ziphindiselwa ekutyeni.

Kwiplanti yokusulungekisa ioyile, umatshini wokucoca i-hydrated unokusetyenzwa kunye nomatshini wokuphelisa i-oyile, umatshini wokuthambisa i-oyile, kunye noomatshini bokucoca ioyile, kwaye aba matshini baludidi lwemveliso yokucoca ioyile. Umgca wokucoca uhlelwe ngohlobo oluphakathi, uhlobo lwe-semi-continuous, kunye nohlobo oluqhubekayo ngokupheleleyo. Umthengi unokukhetha uhlobo ngokuhambelana nomthamo wabo wemveliso efunekayo: umzi-mveliso onamandla okuvelisa i-1-10t ngosuku ilungele ukusebenzisa izixhobo zohlobo oluphakathi, i-20-50t ngosuku lwemveliso ilungele ukusebenzisa izixhobo zohlobo oluqhubekayo, ukuvelisa. ngaphezu kwe-50t ngosuku ilungele ukusetyenziswa kohlobo lwezixhobo eziqhubekayo ngokupheleleyo. Olona hlobo lusetyenziswa ngokuqhelekileyo yilayini yokuvelisa i-hydrated degumming.

IParameter yobuGcisa

Ezona zinto ziphambili zeHydrated degumming (i-water degumming)

3.1 Umthamo wamanzi awongeziweyo

(1) Umphumo wamanzi ongezelelweyo kwi-flocculation: Ubungakanani obufanelekileyo bamanzi bunokwenza i-stable multi-layer liposome structure. Ukungonelanga kwamanzi kuya kukhokelela kumanzi angaphelelanga kunye ne-colloidal flocculation embi; Amanzi amaninzi athambekele ekwenzeni i-emulsification yamanzi-oyile, okunzima ukwahlula ukungcola kwioli.

(2) Ubudlelwane phakathi kwesiqulatho samanzi esongeziweyo (W) kunye nomxholo wegluum (G) kubushushu obuhlukeneyo bokusebenza:

| ubushushu obuphantsi bokumanzisa (20 ~ 30℃) | W=(0)5~1)G |

| ubushushu obuphakathi (60~65℃) | W=(2~3)G |

| ubushushu obuphezulu behydration (85 ~ 95℃) | W=(3~3.5)G |

(3) Uvavanyo lwesampula: Ubungakanani obufanelekileyo bamanzi abongeziweyo bunokumiselwa ngovavanyo lwesampulu.

3.2 Ubushushu bokusebenza

Ubushushu bokusebenza ngokuqhelekileyo buhambelana nobushushu obubalulekileyo (ukuhamba ngcono, ubushushu bokusebenza bunokuba phezulu kancinci kunobushushu obubalulekileyo). Kwaye ubushushu bokusebenza buyakuchaphazela ubungakanani bamanzi ongezelelweyo xa izinga lokushisa liphezulu, inani lamanzi likhulu, ngaphandle koko, lincinci.

3.3 Ubunzulu bomxube we-hydration kunye nexesha lokuphendula

(1) I-Inhomogeneous hydration: I-Gum flocculation yi-heterogeneous reaction kwi-interface yentsebenziswano. Ukuze wenze i-emulsion state e-oil-water emulsion state, ukuxuba ngomatshini umxube unokwenza amaconsi ahlakazeke ngokupheleleyo, ukuxubana ngomatshini kufuneka kuqiniswe ngakumbi xa inani lamanzi elongezelelweyo likhulu kwaye ubushushu buphantsi.

(2) Ukunyaniseka kwe-hydration mixing: Xa udibanisa ioli kunye namanzi, isantya esishukumisayo si-60 r / min. Ngexesha lokuvelisa i-flocculation, isantya esishukumisayo si-30 r / min. Ixesha lokuphendula lokuxutywa kwe-hydration lijikeleze imizuzu engama-30.

3.4 Ii-Electrolytes

(1) Iindidi ze-electrolytes: Ityuwa, i-alum, i-sodium silicate, i-phosphoric acid, i-citric acid kunye ne-dilute sodium hydroxide solution.

(2) Umsebenzi ophambili we-electrolyte:

a. I-Electrolytes inokunciphisa enye intlawulo yombane ye-colloidal particles kwaye ikhuthaze i-colloidal particles to sedimentate.

b. Ukuguqula i-phospholipids engekho-hydrated kwi-hydrated phospholipids.

c. Alum: flocculant uncedo. I-alum inokufunxa i-pigments kwi-oyile.

d. Ukutshiza ngeeoni zetsimbi kwaye uzisuse.

e. Ukukhuthaza i-colloidal flocculation ngokusondeleyo kunye nokunciphisa umxholo weoli kwiiflocs.

3.5 Eminye imiba

1

(2) iqondo lobushushu lamanzi adityanisiweyo: Xa kufakwa amanzi, ubushushu bokongeza amanzi bufanele bulingane okanye buphakame kancinane kunobushushu be-oyile.

(3) Umgangatho wamanzi ongezelelweyo

(4) Uzinzo lokusebenza

Ngokuqhelekileyo, iiparitha zobugcisa zenkqubo ye-degumming zichongwa ngokuhambelana nomgangatho weoli, kwaye iiparitha zeeoli ezahlukeneyo kwinkqubo ye-degumming ziyahluka. Ukuba unomdla wokucoca ioli, nceda uqhagamshelane nathi ngemibuzo okanye imibono yakho. Siza kulungiselela iinjineli zethu zobuchwephesha ukuba zenze ngokwezifiso umgca we-oyile ofanelekileyo oxhotyiswe ngezixhobo ezihambelanayo zokusulungekisa ioyile yakho.